Magnetization technology

着磁技術

The pursuit of efficiency in electric power equipment has become a social requirement, and the improvement of the magnetic flux density of the internal magnets is an issue for motors and generators. By the way, high-temperature superconducting bulk materials can be used as permanent magnets due to the pinning effect, and can capture strong magnetic fields that are difficult to achieve with conventional permanent magnets. However, when superconducting bulk material is incorporated into a rotating machine and used for actual use, it is difficult to magnetize by cooling under a static magnetic field due to functional restrictions of the superconducting equipment, space and weight. For this reason, a magnetizing method by applying a pulsed magnetic field is considered desirable.

電力機器における効率化の追求が社会的要請となって現在、モータや発電機に関しては内部磁石の磁束密度の向上が課題となるため、その改良は簡単に進んでいません。 ところで高温超電導バルク材はピン止め効果によって永久磁石としての利用が可能であり、従来の永久磁石では実現困難な強磁場を捕捉することが可能なため、電力機器の性能向上に対する抜本的な解決策となり得ます。 しかし超電導バルク材を回転機などへ組み込み実使用する際、超電導機器の機能的あるいは空間・重量に対する制限のために、静磁場下冷却による着磁は困難です。 そのため、パルス磁場の印加による着磁方式が望ましいと考えられます。

The superconducting electromagnet used for cooling under static magnetic field, which is necessary for magnetizing superconducting bulk materials, is replaced with a small metal coil and an excitation power supply with a pulse power supply for pulse magnetization. This eliminates the need for superconducting electromagnets and enables inexpensive magnetization. In addition, in general pulse magnetization, since the application of the magnetic field is completed within 1 second, magnetization can be completed in an extremely short time compared to cooling under a static magnetic field, which usually requires several hours. Therefore Pulse magnetization is a promising magnetization technique for practical equipment.

超電導バルク材に対するパルス着磁に必要な装置の構成は、静磁場下冷却に使用する超電導電磁石を小型の金属コイルへ、励磁電源を同程度の大きさのパルス電源へそれぞれ置き換えた形となります。 そのため超電導電磁石が不要となって安価な着磁を可能とします。 加えて、一般的なパルス着磁は1秒以内に磁場の印加が完了するため、通常数時間を要する静磁場下冷却と比べて極めて短時間で着磁を完了可能なことから、実用に向いた着磁技術として有望です。

A pulsed magnetic field is generated by flowing the charge stored in a large-capacity capacitor through a magnetizing coil in a short time. At this time, the pulse magnetizer is to generate an excessive pulse magnetic field that greatly exceeds the magnetic flux density that can be trapped by the superconducting bulk material cooled to an arbitrary temperature below the critical temperature, so the bulk is magnetized in a short time. The problem with this method is that the rapid increase and decrease of the magnetic flux density due to the application of the pulsed magnetic field rapidly increases or decreases the intrusion flux due to the applied magnetic field exceeding the critical magnetic field. Heat generation due to intense movement of magnetic flux penetrating into the superconducting bulk material causes an increase in temperature, resulting in a decrease in trapped magnetic flux density and total magnetic flux, and disturbance in the magnetic field distribution.

パルス磁場は大容量コンデンサに蓄えた電荷を短時間に着磁コイルへ流すことで生み出されます。 このとき、臨界温度以下の任意温度へ冷却された超電導バルク材料が捕捉可能な磁束密度を大きく上回る過剰なパルス磁場を発生させて、短時間での磁場の捕捉を為すというのがパルス着磁法の概要です。 この手法の問題は、パルス磁場の印加に伴う磁束密度の急速な増加と減少が臨界磁場を大きく上回る印加磁場による侵入磁束を急激に増減させ、超電導バルク材への侵入磁束の激しい運動に起因する発熱が温度上昇を招いて捕捉磁束密度と総磁束の低下、磁場分布の乱れを生じさせることにあります。

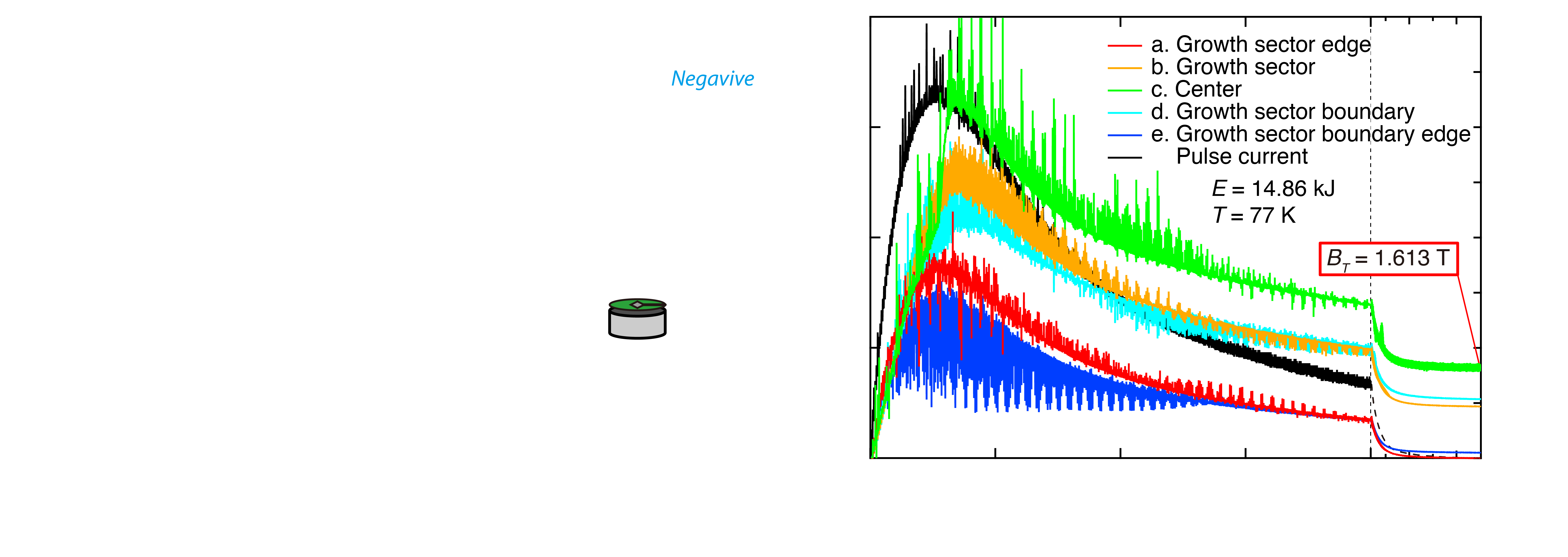

In general, generating a pulsed magnetic field that requires a large amount of energy is not technically easy. We have devised the method and succeeded in significantly improving the trapped magnetic flux density by generating a magnetic field that can be easily captured by the superconducting bulk material instead of the pulse magnetic field that is easily generated. The above figure shows the waveform control pulse magnetization method for that purpose. The sensor placed on the bulk surface trapped the magnetic flux that entered the superconducting bulk material during pulse magnetization, and controlled the pulse magnetic field waveform applied from that state. By this technology, we have obtained a trapped magnetic field that exceeds 90% of the maximum magnetic flux density achieved by magnetization with cooling under a static magnetic field with an elapsed time of about 1/10,000.

一般的に大きなエネルギーを要するパルス磁場の発生は技術的に容易ではないのですが、我々はその方法を工夫し、発生しやすいパルス磁場ではなく、超電導バルク材が捕捉し易い磁場を生み出すことで、その捕捉磁束密度を大幅に向上させることに成功しました。 上図はそのための波形制御パルス着磁法について示しており、パルス着磁の最中に超電導バルク材へ侵入した磁束をセンサで捉えて、その状態を基に印加するパルス磁場波形の制御を行っています。 この技術によって、我々は静磁場下冷却による着磁と比べて90%を超える最大捕捉磁束密度を、1/10,000程度の時間で達成しました。